The demand for automobile energy efficiency and higher emission standards encourages the development of modern engines and drive trains that have lower frictional losses at various contact surfaces. One solution for reducing such frictional losses is to add texture modifications to engine/drive train surfaces that come in contact with one another during operation. However, previous texture-adding techniques have proved to be technically or economically inadequate for automobile engine/driving train operating conditions.

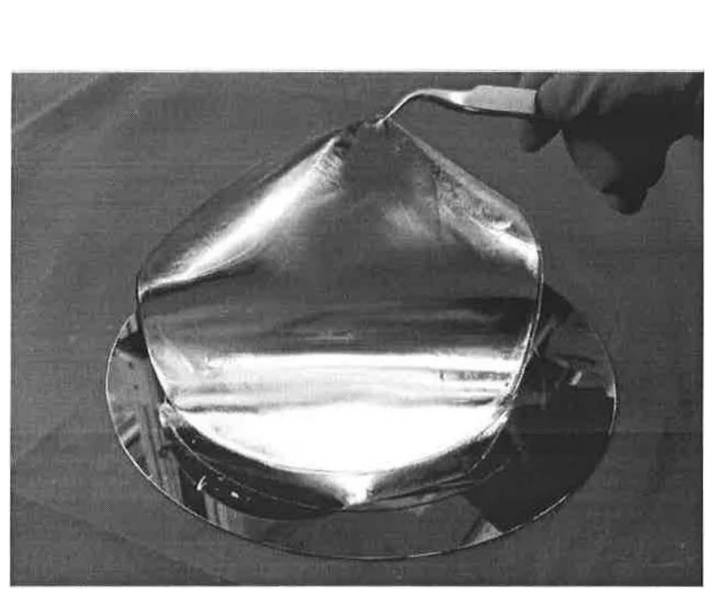

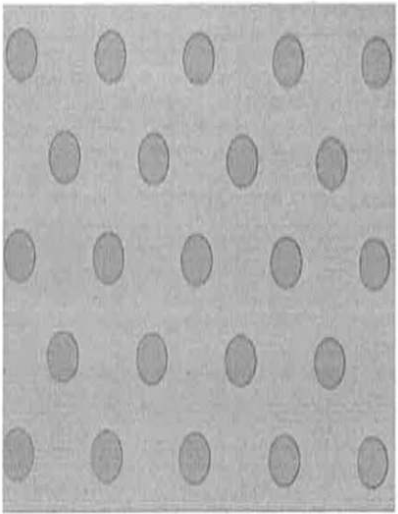

GW researchers have developed technologies for adding unique geometries and materials onto engine/drive train surfaces. Here, these unique geometries and materials change engine surface texture and reduce engine/drive train friction. For example, dimples of varying geometrics and depth can be applied to surfaces of engine components. Furthermore, GW researchers also developed new fabrication techniques for adding such textures onto engine surfaces. One technique is to apply a patterned soft mask onto a large surface (flat or curved including cylindrical rollers surfaces) to be followed by electrochemical etching to imprint the textures onto component surfaces. In addition, a diamond-like-carbon (DLC) film may be applied to the engine turbine component surfaces to reduce friction.

FIG. 1 - Surface Picture

FIG. 2 - Engine Surface under Electronic Microscope

FIG. 3 - Surface Geometry

Applications:

Reducing frictional loss in automobile engines to increase energy efficiency and reduce emission

Advantages:

1. Reduces frictional loss by changing engine/drivetrain surface texture

2. Unique materials and geometries maybe applied to engine surfaces and serves well under engine’s high temperature and pressure operating conditions

3. Fabrication technique for changing engine surface texture include electrochemical etching or adding a diamond-like-carbon (DLC film)

4. Fabrication technique can be precise and time/cost effective, thus applicable to industrial needs