Researchers at the George Washington University and Arizona State University have been developing a family of novel golf ball designs that can reduce drag by as much as 15% compared to traditional designs based on dimples. The new designs will allow for improved aerodynamics performance which can be used to increase the distance the ball travels or to improve the feel of the ball. Dimples have been extensively used on golf balls for the past 100 years ago and their aerodynamic performance has reached a plateau. Nowadays golf balls from different manufacturers have almost identical aerodynamics characteristics. The family of designs invented by the researchers are based on innovative polyhedral shape that have symmetrical behavior and comply with USGA and R&A rules and regulations. In addition, some of the designs do not use dimples and have a very distinct appearance from commercial golf balls in the market.

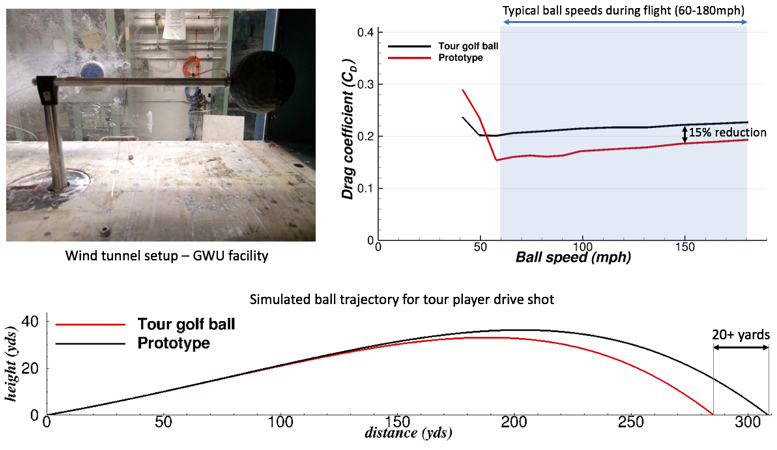

Prototypes based on the novel designs have been tested in the wind tunnel and compared against leading golf balls. The figure plots the drag coefficient of a prototype and a tour golf ball for a range of speeds that are typically experienced by a golf ball on a drive shot hit by a tour player. The launch conditions are very similar to those set by USGA for the distance test. The drag coefficient is consistently lower throughout the entire flight of the golf ball by 15% or more. The drag reduction results in significant gains in carry distance of at least 20 yards.

The global golf ball market has been steadily growing since 2016 and is expected to reach $1.3 billion by 2020. Besides golf balls the technology can be applied to other sports equipment in general where drag needs to be reduced, such as golf clubs or sports helmets.

Applications:

1. Golf Balls

2. Golf Clubs

3. Sport Helmets

4. Other sport equipment in need of drag reduction

Advantages:

Drag Reduction