Researchers at The George Washington University are developing an innovative method to make high purity crystalline flake graphite from low-cost biomass. The novel Graphite technology invented at GW will slash cost of Li-Ion battery grade graphite (99.5% purity) by more than 80% (from about $20,000/ton to $2,500/ton). Considering the “STRATEGIC” nature of this technology and the high demand for Li-ion battery grade Graphite, we believe that in a couple of years this technology can be worth tens of billions of dollars.

The market for graphite, classified as a “strategic and critical mineral” by the US and EU, is expected to reach 4.48 million tons and $17.56 billion by 2020. Graphite is consumed in numerous industries and applications including steel making, batteries, refractories, lubricants, foundry facings, brake linings, pencils, graphite foils for use in fuel cells, laptop computers, valve packings and gaskets, and graphite electrodes for use in, for example aluminum smelting. Graphite is also used as a starting material for the production of graphene, graphene oxide and reduced graphene oxide. Over the last 10 years, battery grade Graphite has become one of the most important “STRATEGIC MATERIALS” for Technology companies. The party controlling Graphite supplies is likely to have a huge advantage over competitors (synthetic graphite is very expensive whereas mining / processing Graphite to battery grade causes extreme damage to the environment).

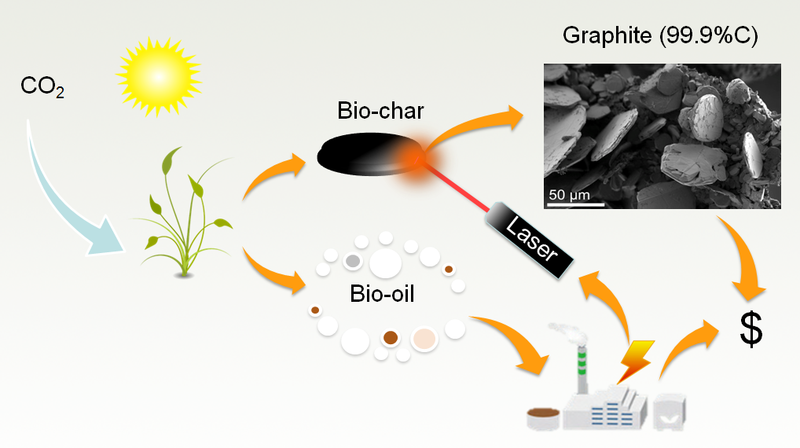

Professor Wagner has invented a method of producing Battery Grade Graphite (purity 99.5%) from inexpensive biomass (e.g. bio-chars) or lignite (an inexpensive coal). A mixture of carbon containing feedstock (e.g. biomass or carbonaceous material) and a catalyst (metal, an alloy or a combination) are illuminated with high power laser radiation (such as from a high power CO2 laser) thereby converting the biomass into flake Graphite of high purity (99.0%) suitable for Li-ion batteries. The estimated production cost for such Graphite is $2,500 / ton – (compared to the current cost of $20,000 / ton).

Applications:

1. Graphite is the primary material in Li-ion batteries.

2. Used in steel making, batteries, refractories, lubricants, foundry facings, brake linings, pencils, graphite foils for use in fuel cells, laptop computers, valve packings and gaskets, and graphite electrodes for use in, for example aluminum smelting.

Advantages:

1. Production of 99.9% high purity / battery grade Graphite.

2. Slashing cost of Li-Ion battery grade Graphite by more than 80% (from about $20,000/ton to $2,500/ton) & environmentally friendly.